Membrane processes today are a well established technology and used as a standard treatment step for industrial and municipal water and wastewater treatment. However, problems still occur making the membrane treatment often chemically, energetically and operationally intensive. Typically over the life of a membrane system, operating costs often become greater than anticipated with membrane fouling representing today the biggest obstacle to a smooth membrane operation. Scaling, organo- and bio-fouling problems remain technical and cost issues that continue to plague membrane technology.

With 20 years of experience, Aquatis can optimise your membrane plant by providing smarter, cheaper ways of delivering your service. Whatever stage you are at in your membrane project, Aquatis can help with the design of a new membrane plant or optimise an existing plant, as part of a troubleshooting, a technical upgrade or a refurbishment.

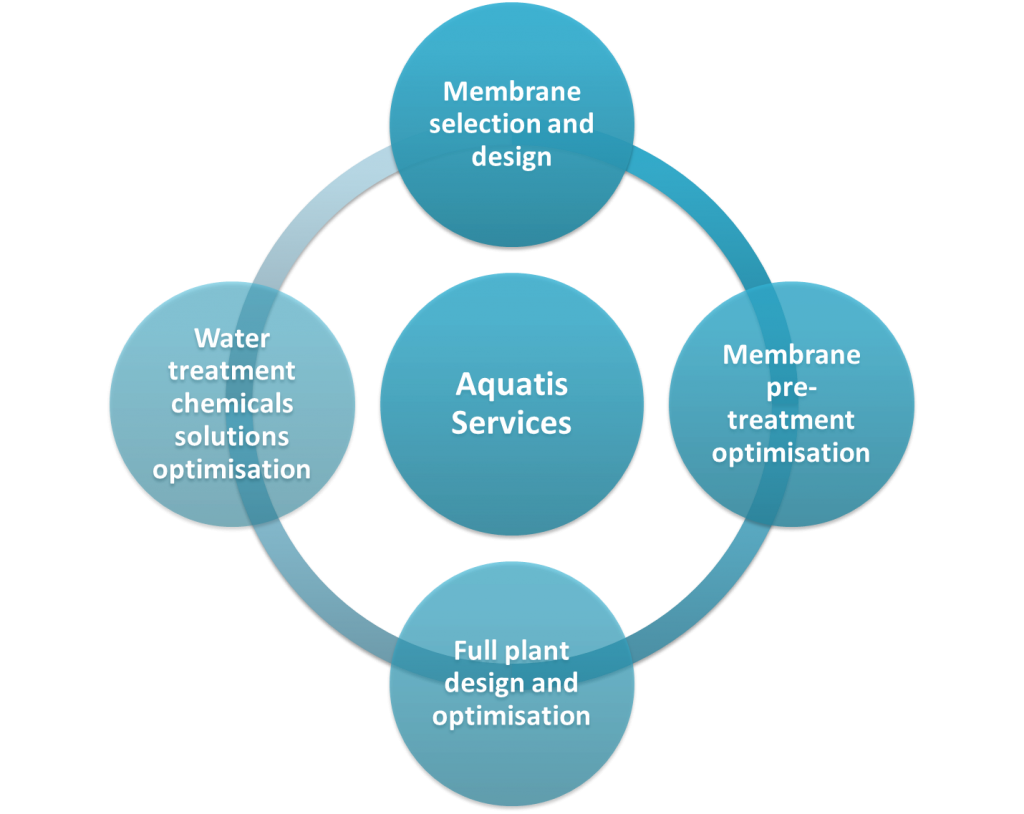

Aquatis offers Industries and Utilities the following services :

- Membrane selection and design

With an ever increasing range of membranes available on the market, selecting the right equipment can be a difficult and costly exercise. Aquatis can help you choose and design the best system for your water treatment plant according to your water specifications, water quality and budget. Membrane lab testing can be conducted as required to ascertain the best type of membranes. - Membrane pre-treatment Optimisation

Often neglected, membrane pre-treatment is a major part of the successful membrane treatment process and should be optimised according to several parameters. To maximise membrane performance, Aquatis can optimise your pre-treatment to improve membrane flux, recovery, and reduce operational costs. - Full plant design and optimization

Aquatis can design and review a full plant, including membrane post-treatment, waste management, as well as associated equipment to ensure best performance. Our experts will propose alternative options for concentrate and waste management, with the aim of minimizing waste, energy, chemicals usage and optimizing the overall performance of the plant. - Water treatment chemicals solution optimisation

Water treatment chemicals can represent a significant part of your operational costs. If the dosage or chemicals selection is not optimised, organic fouling, scaling, biofouling or degradation will reduce the performance of your membranes, and increase operational and maintenance costs.

Aquatis can provide you with independent technical expertise on water treatment chemicals and help select the best chemicals for your treatment process, with the right concentration and sequences.

For wastewater treatment, a disinfection step is often required to prevent biofouling. When the chemicals dosage is not optimized, membrane degradation or biofouling can take place, generating significant operations and maintenance costs. With expertise in online continuous disinfection, Aquatis can help optimise the dosage of disinfection chemicals and prevent membranes from being damaged or having to be replaced.

If required, Aquatis can propose a yearly service contract to look after your overall water membrane process and offer specialist advice to continuously fine-tune the chemicals dosage, improve the membrane recovery and optimise the cleaning and backwash sequences.

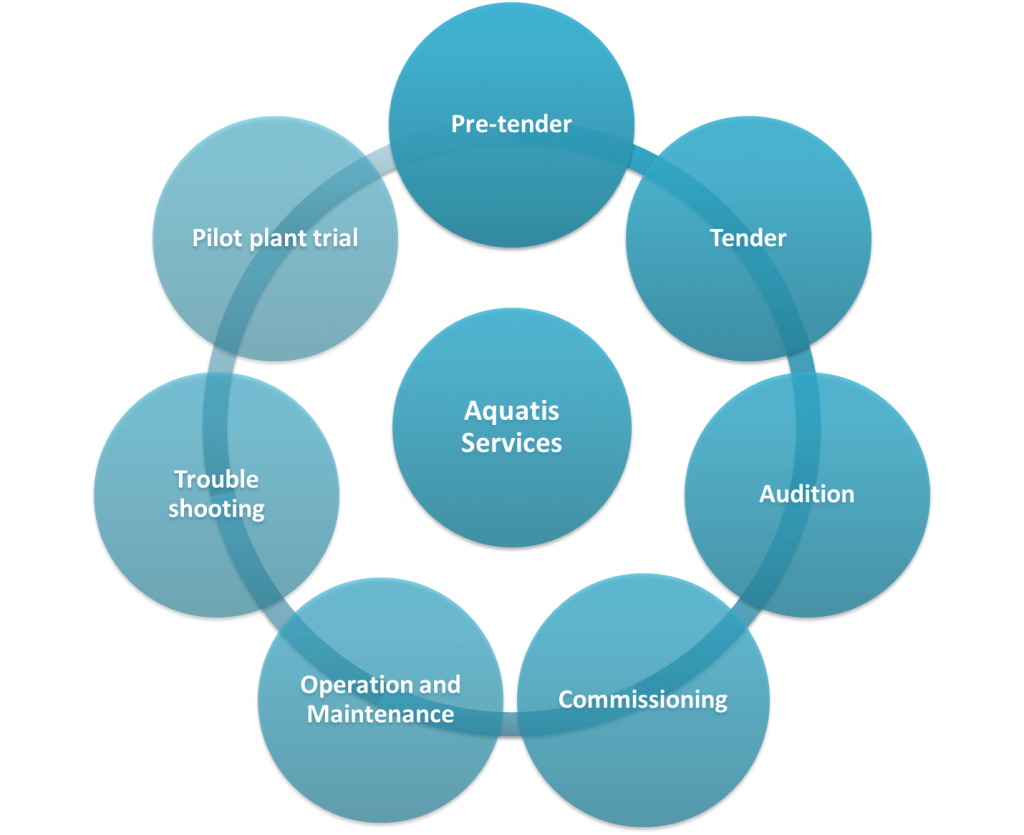

Aquatis can assist at different stages of the project :